Another name for the soft gel encapsulation machine is a softgel capsule filler or encapsulator. The mechanical equipment fills gelatin capsules and is widely used in the nutraceutical and other industries. The contents of these capsules are nutraceutical in nature.

In this article, I define nutraceuticals, discuss the benefits of encapsulation, and walk readers through the process of encapsulating several kinds of nutraceuticals. Additionally, I outline the challenges that manufacturers of nutraceuticals face and offer my recommendations for solutions. Discover the factors you need to consider before buying a soft gel encapsulating machine by reading until the end.

What are Nutraceuticals?

Alt: Fish oil soft gel capsules (Image from Monfocus on Pixabay)

By 2028, the nutraceutical market is projected to grow to USD 595.70 billion. Nutraceuticals are any product made from food sources that offer additional health benefits. Its manufacturers mix pharmaceuticals (food meds) with nutrients (nourishing food ingredients). Nutraceuticals are centered on preventing disease through healthy eating habits.

Usually, nutraceuticals fall into one of four categories:

- Dietary supplements are concentrated powder, pills, soft gel capsules, gummies, energy bars, and liquid products from food sources. The Food and Drug Administration (FDA) in the United States usually regulates dietary supplements.

- Functional foods are nutritional components that have been enhanced, enriched, fortified, or whole. In addition to the conventional nutrients they contain, they assist in preventing chronic diseases and offer other health advantages.

- Farmaceuticals are valuable pharmaceutical products made from genetically altered plants or animals. Genetically altered plants are the source of drugs like insulin.

- Foods intended for medicinal purposes are designed to be taken internally and provided under the guidance of a licensed medical professional. These foods support the nutritional management of a certain illness or condition.

What Are The Advantages Of Soft Gel Encapsulation In Nutraceuticals?

Alt: Portable gelatin melting tank.

Specialized equipment called soft gel encapsulation machines produce nutraceutical soft gel capsules. The capsules’ vegetarian or gelatin shells wrap liquid or semisolid food sources. There are various reasons why the capsules are favored over other forms.

One of the advantages is that soft gel nutraceutical capsules, with their accurate dosage and improved chemical absorption, provide easy digestion. The gelatin breaks down quickly.

Soft gel capsules can accommodate a range of formulas, colors, and sizes. As a result, you receive tasty and simple-to-swallow soft gel capsules. Both adults and children find the soft gel capsules of nutraceuticals attractive due to their color variation.

The sensitive nutraceutical contents within the soft gel capsules are protected from light and oxygen by the gelatin capsule shell. Hence, the components are shielded from physical as well as chemical reactions.

In addition, the soft gel capsules make them easy to swallow by covering offensive tastes and smells. As a result, you can administer certain natural compounds that may have a bitter taste. Or those with strong smells, like garlic and fish oil.

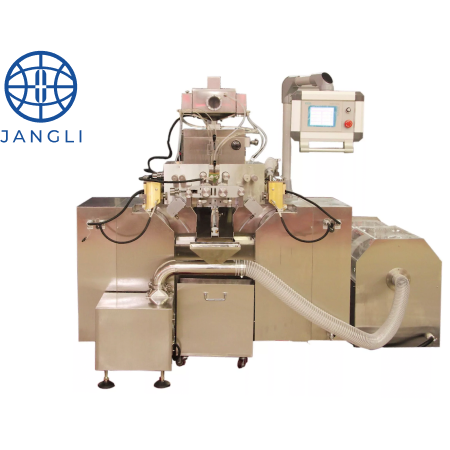

Soft gel encapsulation machine manufacturers, including Jangli Equipment, are now making fully-automated machines. Advanced features, including automatic feeding, filling, sealing, and ejecting systems, are incorporated into these machines. As a result, the machines guarantee constant product quality while lowering human error.

What Is The Process Of Encapsulating Nutraceuticals Soft Gel Capsules?

Alt: Small R&D JL-100II Softgel Making Machine.

The process of creating a capsule shell to enclose and safeguard a certain filler substance is known as encapsulation. It’s not as hard as most people imagine producing nutraceutical soft gel capsules.

Ingredients

- For the shell, you can use vegetable starch (tapioca or pea starch) or gelatin, which is made from animal collagen.

- Functional foods, medicinal foods, nutritional foods, or dietary supplements will make up the fillings.

- Plasticizer is what produces the flexible texture of the soft gel shell. One example of a plasticizer is glycerin.

- The active components are added to a carrier solution. Water, oils, and solvents are the standard carrier solutions.

- Agents for flavoring and coloring: You should use artificial or natural coloring. It might be best to add some flavor, such as sweeteners, essential oils, or other additives, to make the taste more palatable.

- Preservatives. Soft gel makers may choose to increase the shelf life of their products by including a preservative.

- Additives: For stability, think about using an alcohol-based solution, a chemical like Adelyhde, or a protective coating.

Equipment

You will need a soft gel encapsulation machine because you are using the encapsulation method to fill the gelatin capsules with the desired nutraceutical contents. By producing sealed capsules, the machines help to prevent contamination.

There are many different sizes and manufacturing capacities of soft gel encapsulation machines, ranging from large to small.

The Step-By-Step Encapsulation Process

Once you have assembled all the components and made your equipment, you can proceed as follows.

- Before anything else, melt every gelatin component in the melting tank until it liquefies.

- If the fill ingredients are ready, place them in the soft gel encapsulation machine’s hopper. A pump forces the fill material into the injection wedge. The fill material is injected into the die cavities by the pump, and the gelatin ribbons are wrapped around it.

- The soft gel capsules next undergo the drying process. Before being placed on the drying trays, the soft gel capsules are dried in the tumbler drier. The trays are kept in low-humidity drying facilities to eliminate excess moisture and dry the soft gels to room temperature.

- The soft gel capsules are now inspected to make sure none have an incorrect shape or are broken.

- To remove dirt, clean and polish the soft gel capsules by hand or using a soft gel polishing machine.

- Use a soft gel printing printer to imprint your logo on the capsules before packaging.

What Are The Challenges Faced By Nutraceutical Manufacturers?

Probiotics, vitamin D, omega-3 fatty acids, curcumin, polyphenols, and coenzyme Q10 are popular nutraceutical ingredients. However, a few manufacturers have raised challenges when producing nutraceutical soft gel capsules.

I’ve listed some issues and their solutions in the table below.

| Challenge | Solution |

| The low solubility of nutraceutical components can result in problems with absorption and bioavailability. | -To increase absorption, use solubility enhancers and nanoemulsions. |

| -Decrease the soft gel capsules’ average diameter. | |

| Certain nutraceuticals are vulnerable to degradation due to variations in pH or temperature. | – Gradually alter the pH and temperature during formulation. |

| -Apply a special coating to protect fragile materials from external factors. | |

| Nutraceuticals containing fatty acids and oils can oxidize, which results in a bad taste and a loss of potency. | -Use antioxidants (ascorbic acid, vitamin E) and natural extracts. |

| -Create opaque or tinted capsules to reduce exposure to light. | |

| -Ensure that the temperature in the storage is regulated. | |

| Moisture absorption deforms the capsule shell, shortening its shelf life. | -Make use of moisture-resistant exterior components. |

| -Put desiccants or silica gels into the capsule to provide a dry environment. | |

| -Keep the capsules in an environment with controlled humidity. | |

| Some nutraceuticals have tastes and smells too unpleasant for customers to tolerate. | – Use of flavorings and natural sweeteners. |

| -The encapsulation process covers up taste and odor problems. |

Which Factors Should You Consider When Buying A Soft Gel Encapsulation Machine?

No matter how big or small the equipment is, a soft gel encapsulation machine requires a significant initial investment. Therefore, you need to consider a few factors before buying.

- Where you want to put the machine, correctly measure your workstation. Make sure the machine you select will fit in the available space.

- Make sure the machine’s speed matches the rate of the production line.

- Opt for an entirely automated soft gel encapsulation device due to its user-friendly nature. It also makes workflow more manageable. With a fully automatic engine, operating the machine doesn’t require a large workforce.

- Select a machine with a wide range of tooling systems so that you can make soft gel capsules in different sizes and shapes. Even better would be if the device could interface with other systems to increase productivity and save time and effort.

- Additionally, you ought to select a device with a maximum output while using a reasonable amount of electricity.

- Always research the company you are interested in buying from. Given that they can supply high-quality equipment, they ought to be a well-known brand, much like Jangli Equipment.

- Verify that the soft gel encapsulation machine is constructed from a sturdy, oxidation-resistant material.

Examples Of Specialized Nutraceutical Formulations

Many customized nutraceutical formulations are designed to help consumers with particular health issues or targeted health benefits. These formulations use certain components, delivery methods, and dosages.

I’ve highlighted some specialized formulations and their intended health benefits in the table below.

| Ingredients | Benefits |

| Curcumin (turmeric extract), glucosamine, omega 3-fatty acids, collagen peptides. | -Aids in the treatment of ailments including osteoarthritis. |

| -Reduces inflammation and soreness in the joints. | |

| -Enables shared mobility. | |

| -Improves cartilage health. | |

| Zinc, vitamin D, beta-glucans, echinacea, vitamin C, elderberry extract. | -Aids in the body’s infection defense. |

| -Decreases the length and intensity of colds and the flu. | |

| -Fortifies the immune system. | |

| Probiotics, digestive enzymes, prebiotics. | -Decreases bloating. |

| -Maintains a robust immune system. | |

| -It improves digestion. | |

| -May reduce irritable bowel syndrome symptoms (IBS). | |

| Iron, B vitamins, green tea extract, adaptogenic herbs. | – Aids in lowering depression and anxiety. |

| -Enhances vitality levels. | |

| -Decreases fatigue. | |

| -Improves mental vigor and physical health. | |

| Collagen peptides, ceramides, vitamins, antioxidants. | -Minimizes aging symptoms. |

| -Promotes the health of the skin. | |

| – Encourages skin suppleness. | |

| – Enhances hydration. |

The development of these nutraceutical formulations has its basis in scientific research and clinical studies. Thus, I would advise speaking with nutritionists or medical professionals if you require these specific formulas.

Conclusion

The nutraceutical industry is expanding rapidly. If you are a manufacturer of nutraceutical products, you need a machine that you can trust. Your ideal machine is a soft gel encapsulation machine.

Ensure that you have adequate room, that the soft gel encapsulation machine is fully automatic, and that its energy consumption is low before deciding to buy it. It is ideal for the machine to be made from a sturdy material, such as stainless steel.

Frequently Asked Questions

- How is the packing of soft gelatin capsules done?

The optimum method is to place the soft gel capsules in foil-shielded trap blister packaging that is safe, tamper-resistant, and secure. Before wrapping them with stiff trap card blisters, the capsules are first bundled in “foil” blisters.

Blister packs are composed of thermoformed polymers and are produced with plastic or aluminum foil lids that are easy to tear with your hands.

- Do soft gels dissolve in water?

Soft gels do indeed dissolve in water. Since soft gel capsules are meant to dissolve in the small intestine or the stomach, they are water soluble.

The soft gel capsule dissolves in water in around twenty to thirty minutes. When the shell comes into touch with water, it begins to absorb it, swells, and finally dissolves.

The soft gel capsules should not be crushed or chewed upon as this will cause improper systemic absorption.

- What is the process of encapsulation of soft gelatin capsules?

Melting the gelatin in the melting tank starts the process. After that, the machine is fed the melted gel, which forms two thin gelatin ribbons.

Upon completion, the ribbons are continually fed between two spinning die cylinders and go over a number of rollers. The two sides of the capsules are formed by the die cylinders, which also set the size and shape of the capsules.