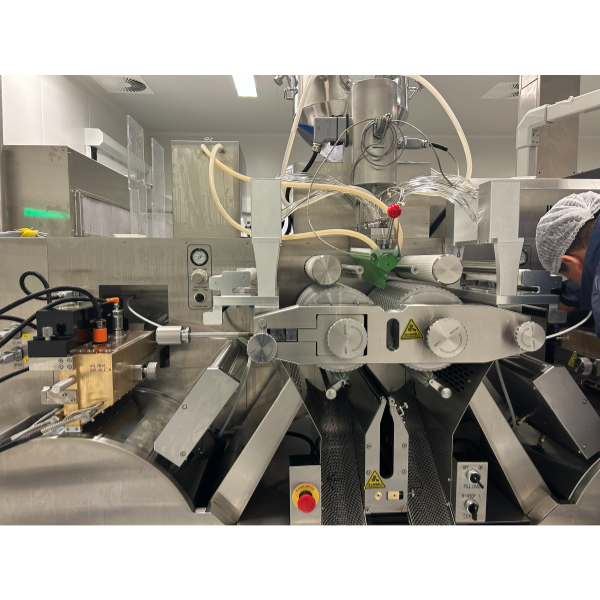

Alt: The JL-250II Softgel Encapsulation Machine.

One of the machines that is commonly used in soft gel encapsulation is the JL-250II. It is used in various industries, including veterinary, nutraceutical, cosmetic, paintball and pharmaceutical, for producing various consumer goods.

Market research indicates that the soft gel encapsulation industry will be worth around USD 178.39 billion in 2032. As a result, the majority of machine manufacturers, including Jangli Equipment, work hard to provide their customers with high-quality machinery.

Hence, I discuss the JL-250II soft gel encapsulating machine in this article. I will explain how to set up and run the JL-250II encapsulating device. I also clarify how to avoid machine failure and what causes it. I’ve included a list of precautions in the article that you and your staff should follow to avoid damage and injuries.

Overview of the JL-250II Softgel Encapsulation Machine

The JL-250II softgel production line consists mainly of the main machine, tumble dryer, conveyor, electrical control system, pneumatic mold(die roller set), and cooling system. It is a high-volume production machine. Let us now look at the various machine parts.

Main Machine

The main machine includes the body, the machine head, feeding systems, right and left gelatin rollers, encapsulation part, gelatin box, lubricating system and cooling system.

- Machine body: Supports the whole equipment. A motor is fixed on the left side and is the main power source.

- Lubricating system: It supplies the liquid paraffin oil to the bearings and gears of the machine’s body and head.

- Machine head: It is the core of the main machine and helps to redistribute the power to the feed pump and the rolling molds.

- Feeding systems: Consists of the material hopper, feed pump, feed pipe and feed plate unit.

- Gelatin box: Uniformly apply the liquid to the turning gelatin skin wheels and form the gelatin skins.

The best way to ensure the longevity of your machine is by employing qualified personnel trained to operate it. The machine operators should be familiar with the machine’s operations.

Conveyor Unit

The unit feeds the soft capsules and comprises the conveyor body, stainless conveyor, speed-reducing motor and adjusting mechanism. The adjusting mechanism is used to tension and adjust the stainless conveyor.

The delivered soft gel capsules are sent to the wind conveyor through the conveyor pipe.

Tumble Dryer

The qualified soft gel capsules are sent automatically to the shaping and drying rotary caging.

Electrical Control Cabinet

The cabinet contains the electrical system and instruments to control the operation of the capsule machine.

The cooling system to cool the gelatin skin wheel is in the lower part of the electrical control box.

Cooling System

It has automatic temperature control, and the cooling system pumps the coolant into the gelatin skin rollers. By doing so, it constitutes a circulation loop for stable temperature control.

How To Install And Set Up The JL-250II Softgel Encapsulation Machine

The JL-250II soft gel machine is suitable for large quantity and commercial scale soft gel production. Installing the machine will require well-trained and authorized personnel with the necessary qualifications.

Before installing, ensure that the following requirements are met.

- The ground surface where you place the machine should be level and smooth.

- There should be suitable connections for electric current and other energy supply. The whole machine consumes electricity of about 15Kw. Hence, the factory buildings need a power supply of 380V and 220V.

- In the rooms where the machine is, there should be air conditioning equipment to ensure that the room temperature remains below 77°F (25°C). The ideal relative humidity should also remain below 60%.

- Once the JL-250II machine arrives at your factory, check for any damaged parts.

- Prepare the necessary mounting tools and materials.

The next phase is the installation process:

- Once the JL250II soft gel machine has been placed down, you must level it using screw-supporting jacks under the supporting base. Remember to disconnect the power supply before working on the machine.

- Ensure the following parts are placed correctly per the graph below:

| Machine Part | Installation Position |

| Conveyor unit | -Located at the front of the main machine. |

| Air blower | -Placed at the upper part of the hopper. |

| Gelatin residual barrel | -Placed at the front side of the main machine, lower side of the conveyor unit, and below the net pulling shaft of the main machine. |

| Shaping rotary caging | -Fixed at the back left side of the main machine. Facing the left side of the main machine. |

| Frequency adapter | -Connected to the main machine. |

| AC voltage stabilizer | -Connected to the main machine. |

- After confirming all the equipment is in place, connect all cables correctly.

- Put the power back on, ready to carry out a test run. The machine must be empty for you to carry out the test run.

- Once the test run confirms that the machine is running smoothly, you can start your normal operations. If you notice an issue as you run the test run, stop the machine immediately and start on the repairs. Run another test after two hours. If no more problems arise, the machine is ready for use.

How To Operate The JL-250II Softgel Encapsulation Machine

After installation, you can start using the machine for your operations. However, you should ensure that the people operating the JL-250II are qualified to do so. No overloading should occur when the machine is in operation.

The materials for making the soft gels should be evenly and appropriately fed into the machine. Failure will lead to the machine getting jammed and not working. When the machine is on, pay particular attention to the rising temperature and any change in the noise of the motor.

Before starting the machine, confirm that the liquid paraffin oil is not less than ⅔ of the height of the lubricating oil tank. The casing of the feed pump, the left oil roller box, the gears at the upper part of the machine head, and the paraffin holes at the upper part of the beam should have a sufficient amount of paraffin.

How To Prevent The JL-250II Machine Failure

Like all machines, the JL-250II needs constant maintenance and cleaning. When you don’t do regular cleaning and maintenance, it can lead to regular machine failure. The common reasons that can lead to machine failure are:

- Power issue: When there is an inconsistent power supply, the machine’s electrical components are affected. Faulty wiring, incorrect components, or any issue with the electrical system can lead to power disruptions, causing damage to the JL250II.

- Incorrect machine setup: If you don’t have professionals installing your machine, it’s possible to misalign machine components. You might also have the inaccurate calibration of dosing pumps, sensors, and other critical components.

- Mechanical issues: Like all machines, soft gel encapsulation machine parts will suffer wear and tear over time. When machine parts are insufficient or improperly lubricated, they are likely to have mechanical damage.

- Lack of maintenance: Inadequate cleaning and lack of regular maintenance often leads to machine failure. Build-up and contamination in the machine parts will cause damage.

- Software/system failures: Lack of professional use can lead to machine control software errors. Any issues with the electronic control system will also lead to system or software failure.

So, how do you perform maintenance on the JL-250II soft gel encapsulation machine? If you want to ensure that the machine functions for a long time, below are the tasks you must perform.

- The first and most important thing is always to refer to and follow the manufacturer’s maintenance manual for specific instructions and schedules.

- Cleaning the machine parts regularly prevents the build-up of residue and contaminants. Remember to use approved cleaning agents and follow the recommended cleaning procedures to prevent damage from occurring.

- Lubricate moving parts to prevent friction and wear. Use the lubrication agents recommended by the manufacturer simultaneously following the lubrication schedule in the manual.

- Regularly inspect the various machine parts for wear and tear. If you notice any signs of deterioration, replace them.

- Ensure that all machine components follow proper alignment. That is because misalignment can lead to operational issues affecting the quality of soft gel production.

- Proper calibration plays a huge role in maintaining accuracy in the encapsulation process. Therefore, you must regularly calibrate dosing pumps, sensors, and other critical components.

- Confirm and ensure that the machine’s control software is always up to date. You should promptly address any software-related issues following the manufacturer’s recommended updates.

- The machine operators should have proper training on the proper usage of the machine and how to perform basic maintenance. Request the machine operators to report any abnormalities or issues to you for timely action.

- You need to have proper records for when you carry out maintenance. These records will help you track the machine’s performance and identify patterns or recurring issues.

When performing the machine’s maintenance, always prioritize safety. Therefore, if you encounter issues that cannot be sorted during your routine maintenance, You can consult our technical support for assistance.

Safety Precautions To Observe When Using The JL-250II Machine

Manning, the JL250II machine with specially trained people is the most recommended way. In this manner, both significant machine damage and worker injuries are prevented. Both may cause a significant loss of capital. Ensuring the machine is not left unattended is an important safety precaution.

There are a few precautions that you and your staff need to follow. A handful are highlighted in the table below.

| Personnel | Machine |

| Training on machine operation and emergency procedures should be provided to machine operators. | Avoid making any reconstruction or configuration changes to the machine. Contact us so we can assign you to someone who can help. |

| Only competent individuals should be permitted to perform installation, operation, and maintenance. | Avoid using the machine for any other function besides encapsulating soft gel. |

| If someone is not mentally or physically healthy, do not permit them to operate on the equipment or be near it. It is possible for there to be human injuries or equipment damage. | Ensure every safety device is installed and functioning properly before turning on the machine. If not working properly, you ought to get new ones. |

| Let there be sufficient lighting in all working areas. | The machine should not be placed in a wet environment or one where it will contact water. |

| The machinery personnel should wear no loose-fitting clothing, long hair, or jewelry. Instead, provide them with shoes, gloves, helmets, and protective clothes. | You should only operate the device at the recommended speed. |

| A list of emergency phone numbers, including the fire department’s, ought to be placed in the working area. Additionally, the operators must know what to do in an emergency. | Pay close attention to high-voltage equipment and components under pressure. |

Conclusion

The JL250II soft gel encapsulation machine is easy to operate, clean and maintain. This is only possible when you use qualified personnel to man the machine.

When you buy from us at Jangli Equipment, we help you to install and perform a test run. We also offer after-sales services for all our machines. The JL250II comes with a one-year warranty.

Frequently Asked Questions

- How can you accomplish uniformity of soft gel using the encapsulation machine?

Ensure that you measure the ingredients precisely. Capsules may become compromised by any increase or decrease in components. Follow the recommended procedure at the recommended temperature and speed.

You won’t receive defective soft gel capsules if the machine and accompanying equipment are cleaned and maintained regularly.

To ensure the production is under control, carefully operate the tooling system with servo motors and miniature pumps.

- What are the different supporting equipment for soft gel encapsulation machines?

Drying trays, a tumble dryer, a soft gel polisher, a soft gel inspection machine, and a soft gel pulverizer are among the accessories that come with the main soft gel encapsulation machine.