Due to the continuous deterioration of the global living environment in recent years, people are paying more and more attention to health and have an increasing demand for health care products. Soft capsules, as the mainstream form of health care products, are becoming more and more popular; the market size of softgel has experienced rapid growth in recent years, growing from US$7.777 billion in 2023 to US$8.38 billion in 2024 and is expected to reach US$11.62 billion by 2028 (Quoted from Global Softgel Market Trends 2024, Forcast To 2023). So softgel production line is becoming more and more popular and knowing this kind of equipment well before starting your softgel machine and other supporting device purchasing is very important. Here we will introduce all you want or need to know about softgel production line.

1. What Are Softgel Production Lines?

Softgel production line is used for softgel encapsulation! It is an automated production line composed of multiple unit units, which mainly includes capsule forming, filling, sealing, adjustment, testing, packaging and other links. Among them, the capsule forming unit mainly uses a capsule belt with drug medicine to drive the capsule belt into a specific shape and size through a rotating die roller mold. The filling unit mainly fills the capsule with an appropriate amount of medicine or nutritional and health food, and then closes the softgel. The adjustment unit makes the production line smoother through lubrication, cleaning and other tasks. The detection unit performs quality inspection on the softgel capsules on the production line to ensure product quality stability. The packaging unit packages, labels and stacks qualified capsules.

2. What Equipment Does The Softgel Production Line Include?

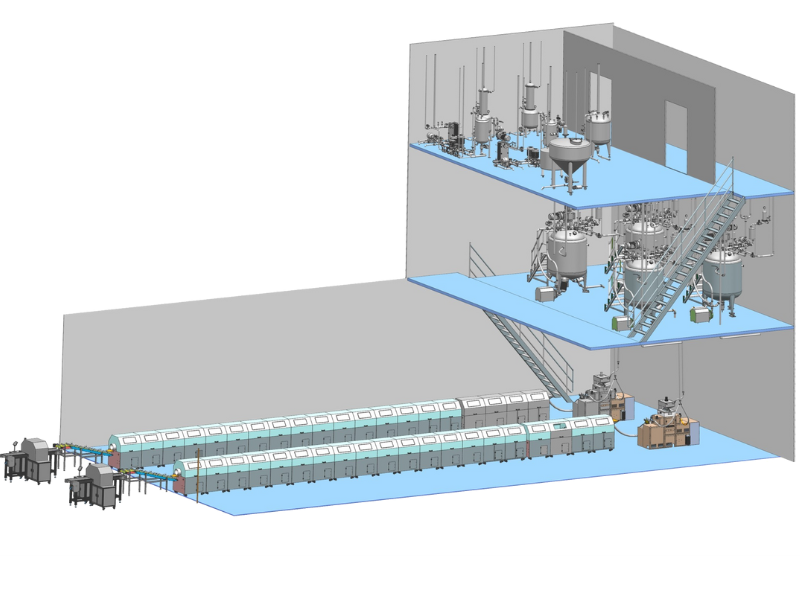

The soft capsule production line is not one piece of equipment, but consists of many production units and many single pieces of equipment. The entire production line consists of

- Gelatin melting and medicine preparation system

- Soft gel encapsulating system

- Softgel drying system

- Sorting system

- Cleaning system

- Packaging system

- Recycling system.

Among them, the gelatin melting system, capsule encapsulation system and drying system are essential units. Without any one of them, soft capsule production cannot be successfully completed. Several other units and equipment companies can decide according to their own specific circumstances. For example, some soft capsule manufacturers only produce oil products and do not need to stir, heat and mix the filling contents in advance, so they do not need a medicine preparation system; some manufacturers have a relatively small output of soft capsules and high product quality. After drying, it can be packaged directly, so there is no need to equip a soft capsule sorting system; some capsule manufacturers do OEM processing, and all softgel products are packaged in large batches and then shipped to the customer’s factory for delivery, so there is no need for a capsule sorting system. Capsule blister packaging machines, soft capsule bottling lines and other subsequent packaging systems, etc.

GELATIN MELTING SYSTEM:

The gel melting system consists of gelatin melting tanks(gel melters), hot water tanks, gelatin service tanks(gel tanks), and gelatin coloring machines(gelatin color mixer).

Gelatin melting tank can also be called gelatin melter. It is used to melt gelatin particles into gelatin liquid or gelatin solution and it is with heatings jacket and mixer and gelatin particles will be melted with water while heating and mixing. According to production capacity the manufacturers can choose different sizes melting tanks, from 60L to 100L 200L 300L 400L 500L 600L 800L 1000L 1200L 1500L to 2000L. And according to the size of the gelatin melters, there are electric heated and hot water heated methods to heat the tanks up. For smaller sizes of gelatin melting tanks electric heating is faster and more convenient while for big sizes of gelatin melters hot water circulation heating method is faster and more suitable because hot water circulation makes the temperature even and stable.

Hot Water Tanks are used for supplying hot water for the heating jacket of gelatin melting tanks. It’s not necessary when the gelatin melters are electric heated. There will be a hot water circulating pump to circulate hot water between gelatin melting tank and hoy water tank. Hot water tanks are always electric heated and some softgel manufacturers may need it gas heated and we can modify it according to clients’ special requirements. And hot water tank, hot water circulation pump, vacuum pump and vacuum condenser are together called a gelatin melting supporting unit.

Gelatin Color Mixer is also called gelatin coloring machine. It is used for mixing the colorant or pigment into the melted gelatin solution and make it even. This equipment is not necessary when softgel producing factories make transparent softgels only.

Gelatin Service Tanks are sometimes called gelatin tank or gel tank for softgel. It’s used to store gelatin liquid when gelatin liquid is ready in the gelatin melting tank and the gelatin service tanks will be transferred to gelatin encapsulation room filled with gelatin liquid and connected to softgel encapsulation machine. Comparessed air wil be used to push the gelatin out of the tank and transferred to the gelatin machine for further softgel production.

MEDICINE PREPARATION SYSTEM

Softgel filling preparation system consists of medicine mixing tanks and medicine service tanks. As you may know,medicine(or fillings) can be encapsulated into softgel capsules must be oil or oily suspension or oily paste. Medicine preparation tanks are used to mix the fillings with the oil and make it even and smooth. For large softgel production, closed medicine mixing tanks with same structure as gelatin melting tank are needed, so that the medicine and oil can be sucked into the tank automatically and the ready medicine liquid can be translated to the medicine service tanks(fill tanks) automatically by compressed air.

SOFTGEL ENCAPSULATION SYSTEM

Soft gelatin encapsulation system is the core system in the whole production process. Soft capsules will formed here. And this system consists of soft gelatin machine and softgel shaping and initial drying tumble dryers.

Softgel Encapsulation Machine is used to make the gelatin liquid into gelatin film one the casting drums and fill medicine into between the two films and form capsules by the pressing of die roller sets installed on the machine. The die roller sets decide the shapes and sizes of the soft capsules. By designing the die roller cavities, we can make the capsules round, oblong, oval, twist, fish, heart, star or any animal shapes. There are different sizes of soft gelatin making machines available and the softgel manufacturers can buy according to their production capacity requirements.

Softgel Shaping and Initial Drying Tumble Dryer. When softgels just encapsulated and drop from the softgel machine, they are fragile and soft and easy to deform and break, so we use these rotating tumble dryers to help capsules to take shape and realize initial drying. The main principle is to drive the cages to rotate through the motor, thereby using the rotating cage to drive the soft capsules inside to rotate, and under the action of the bellows, the soft capsule is cooled and the moisture on the surface of the capsules is reduced, thereby achieving the shaping effect, thereby preventing softgels from adhering to each other and affecting product quality and appearance.

SOFTGEL FINIAL DRYING SYSTEM

After shaping and initial drying, the softgel capsules are strong enough to go for next step–final drying. Traditionally, there are two methods for softgel final drying, one is tray drying and the other is inline tumble dryer drying and both drying methods require a low temperature and low humidity environment to achieve the predetermined drying effect. So in the softgel drying room, there should be dehumidifier and air conditioner installed to control the room temperature to ~19°C and relative humidity to 20%.

But Recent years, JANGLI has developed a new softgel drying method–intelligent tumble dryer drying system, this drying method is essentially tumble dryer drying, just with a built-in air conditioning and dehumidification system, which means we can control the temperature and RH inside the closed baskets and dry the capsules much faster.

Softgel Tray Drying: After initial drying, the capsules can be spread flat on softgel drying trays to dry. JANGLI’s soft capsule drying trays are made of food grade PP/PT material and with small holes for air easy to go through. The trays are stackable to save space, and the stacked trays can be put on the matching trolleys and each trolley can take 33 trays. And there should be a drying room for the trays with temperature controlled to 19°C and relative humidity controlled to 20%. And capsules need to be artificially turned over at regular intervals, so that they can not be deformed.

Softgel Tumble Dryer Drying: Since the tray drying method requires a lot of space and manpower, and the drying time is very long, the capsules are prone to adhesion and deformation, so recommend to use inline tumble dryers for softgel final drying. The drying tumbler will allow the capsules to continue rotating during the drying process, preventing adhesion and extrusion deformation. It also saves labor, improves softgel drying efficiency, and ensures drying effects. JANGLI’s double deck tumble dryers can save space to the greatest extent.

Intelligent Tumble Dryer: By using JANGLI’s new designed intelligent tumble dryer, the manufacturers do not need a special drying room and no need to control the temperature and humidity inside the room. The built-in dehumidifier inside the dryer will keep taking the humidity from the capsules out and sending new dry air in, which dramatically improves the drying effect and shortens the drying time and saves the space.

3. How To Choose The Right Softgel Production Line For Your Business?

Deciding what stage your softgel production project is at and your production capacity requirements are very important. If you have just entered the soft capsule industry and want to start with small batch production and the production demand is not high, then it is recommended that you buy an R&D softgel encapsulation machine. This small soft capsule machine can be used for testing and research and development of new products. It is used for formal production of small batches and is suitable for learning the use and operation of soft capsule equipment without wasting a lot of raw materials.

But if you are new to this softgel industry but already have many potential customers and have a large demand for soft capsules, or you already have some softgel making equipment and need to expand production scale, then we recommend that you buy a large fully automatic softgel machine, this kind of equipment has high output, high degree of automation and good stability. It can save labor, time and raw materials to the greatest extent, and achieve large-scale production. The output list of different soft gelatin machines are as follows for your reference:

| Capsule | Output/h (4rpm) | Output/h (5rpm) | Output/h (4rpm) | Output/h (6rpm) | Output/hour (6rpm) | |

| Shape | Size | JL-100II | JL-150III | JL-250II | JL-250III | JL-300III |

| Oval | 6# | 24,000 | 86,100 | 140,400 | 210,600 | 333,870 |

| 8# | 22,800 | 63,000 | 120,960 | 181,440 | 287,640 | |

| 10# | 17,280 | 61,200 | 106,080 | 159,120 | 252,260 | |

| 14# | 15,360 | 48,000 | 92,160 | 138,240 | 219,150 | |

| 16# | 15,360 | 46,500 | 81,840 | 122,760 | 194,610 | |

| Oblong | 8# | 15,840 | 49,200 | 100,800 | 147,600 | 233,990 |

| 10# | 14,400 | 48,000 | 98,400 | 126,000 | 199,760 | |

| 16# | 13,680 | 32,400 | 84,000 | 88,200 | 139,820 | |

| 20# | 8,160 | 30,600 | 58,800 | 99,360 | 157,510 | |

| 22# | 7,200 | 41,400 | ||||

| Round | 38# | 9,120 | 28,800 | 66,240 | 88,200 | 139,820 |

| Tube | 20# | 4,800 | 86,100 | 58,800 | 58,800 | 93,210 |